Despite the constraints of the current economic landscape – and some OEMs reporting a decline in sales – demand for high-capacity telehandlers remains mostly steady and stable across North America.

“While demand isn't quite at last year's peak, it’s still steady,”says Lee Tice, product manager, JCB North America.“High-capacity telehandlers remain essential on today's large-scale jobsites, and while the urgency may have cooled slightly, the need for machines that can reliably lift heavy loads to height hasn’t gone away.”

ALH sat down with telehandler manufacturers to get their take on what’s impacting – and propelling – the 10,000-pound-plus telehandler market, their outlook for the year ahead, new product launches and trends within the high capacity telehandler sector. Here's what they had to say.

Last year, demand for high-cap telehandlers in N.A. was quite robust, but we’re seeing a bit of a slowdown in OEM sales this year. What's the current market like?

Amalija Kopac, senior global product manager, Genie: Historically, telehandlers in the 10,000-pound-and-higher range required larger engines that needed DEF. The introduction of the 74 hp DEF-free engine in 10k machines, such as Genie’s GTH-1056 telehandler, really helped accelerate demand for high-capacity telehandlers. That demand has continued to grow because telehandlers in the 10,000- and 12,000-pound category are so versatile on jobsites.

Lee Tice, product manager, JCB North America: We’re not seeing economic uncertainty stop progress on the ground. Jobsites are still active, steel is still going up and materials are still moving. While there may be some hesitation in capital spending, it hasn’t translated into a slowdown in work.

That’s especially true in sectors backed by infrastructure funding –those projects have momentum, and they’re going to move forward regardless of short-term economic signals. The construction sector has shown real resilience, and high-capacity telehandlers remain vital tools in keeping those jobsites productive.

John Boehme, senior product manager –telehandlers, JLG: Despite the constraints of the current economic landscape, the market for high-capacity telehandlers has maintained a steady demand. Although general construction sites and bridge-building projects continue to heavily use these machines, these larger and more powerful telehandlers are increasingly being used in adjacent and specialty industries, like mining, quarries, wind and solar farms, energy exploration and extraction, log handling, waste and recycling.

The ongoing demand for higher-capacity telehandler models can be attributed to the growing size and scale of materials being handled on various project sites. Today, high capacity telehandlers are being utilized to perform tasks traditionally carried out by small rough-terrain cranes, excavators and wheel loaders equipped with forks, saving time, money and labor by allowing operators to accomplish multiple tasks with a single machine.

Matthew Lyons, CFO, Magni Telehandlers:

The current issue in the market is not a lack of demand but rather widespread uncertainty. Government policies are changing not just quarterly or monthly, but literally on a daily basis. This constant flux creates a high degree of uncertainty, which markets and industries generally find unfavorable. Planning becomes extremely challenging when so many variables are in a constant state of change.

What the construction industry, stock market, and OEMs urgently need is a clear and consistent approach to trade, imports, interest rates, and other critical factors. We anticipate that a more stable environment will emerge in the short term, leading to a release of pent-up demand in Q3 and Q4. This would differ from typical second-half purchasing patterns.In the heavy-capacity telehandler category, we are already seeing an increase in inquiries about availability. This strong interest indicates there is genuine demand for the product, provided that ongoing projects continue as planned.

Cole Renken, GM, Merlo America: Economic uncertainty has tempered equipment purchases across some regions, particularly for rental fleets and large contractors carefully evaluating capital expenditures. Volatility in steel prices, global shipping delays and ongoing workforce constraints continue to impact product and delivery timelines. That said, certain sectors like renewable infrastructure and warehousing remain resilient and continue to drive telehandler demand, especially for high-capacity models.

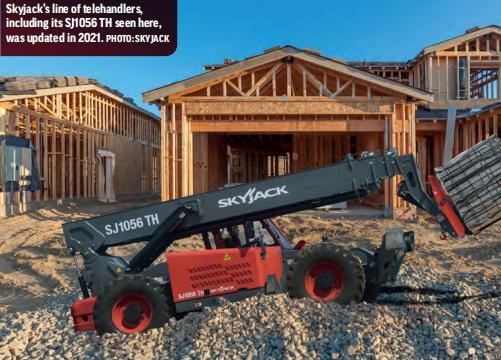

Malcolm Early, VP of marketing, Skyjack:

In terms of telehandlers as a whole, activity lessened in the latter part of 2024 and that seems to have continued in to 2025. The current economic uncertainty plays a role.

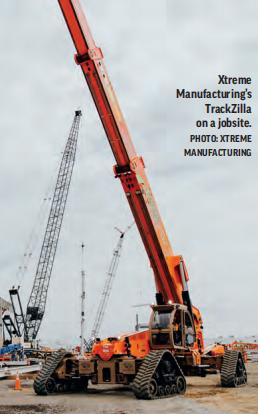

Jeffrey Eckhardt, VP and chief engineer, Xtreme Manufacturing: The market is currently soft,with some hesitation tied to broader economic uncertainty regarding long-term impact from the newly introduced tariffs. That said, I believe this is a short-term adjustment period. As supply chains stabilize and more manufacturing returns to the U.S., we’re likely to see renewed demand for both industrial facilities and the infrastructure to support them. This shift should drive steady growth across construction sectors. While there may be near-term caution, the fundamentals point to a strong rebound, especially as consumer and investor confidence strengthens and large-scale projects proceed.

Will the high-capacity sector undergo any major changes in the coming year?

Kopac: Trends from other heavy-duty equipment types are making their way into telehandlers.

This includes a focus on safety enhancements, like backup cameras, seatbelt recognition (the machine recognizes when you don’t have it engaged), and load management systems.

Tice: High-capacity telehandlers are some of the most straightforward, hardworking machines on

the jobsite – and that’s by design. They’re built to be intuitive, reliable and easy to maintain, because the people operating them need to get the job done without added complexity. We don’t see that fundamental simplicity changing anytime soon. Operator training and certification requirements may evolve slightly, especially as regulations catch up with newer technologies, but these machines are still among the most accessible tools in a fleet.

Boehme: As the high-capacity equipment market continues to be focused on ROI, as defined not only by the initial acquisition cost but also by the total cost of the product over its lifetime. Rental company owners and owners/operators are paying more attention to the versatility of each piece of equipment, the productivity gains it can provide and its retained value. The demand for high-capacity telehandler models that offer equipment owners a greater ROI will drive changes in this market.

Lyons: Load-sensing technology is already a standard feature on scissor lifts and boom lifts—and it should be mandatory on telehandlers of every size, especially high-capacity models. This technology is designed to ensure that machines operate within safe limits, calculating the maximum weight they can lift and the safest position for that weight. Expecting operators to manually perform these complex calculations is not only unrealistic but also dangerously irresponsible.

It is baffling that the industry continues to accept a scenario where contractors lift 10,000+ pounds without any safety or monitoring mechanisms, aside from the obvious danger sign of the rear tires lifting off the ground. This is a clear safety failure.

The American worker is the backbone of the construction industry, and we must do everything in our power to keep them safe. While innovation and job site advancements will continue, our first priority should be mandating safer working conditions, starting with requiring load-sensing technology on all telehandlers.

Renken: There are a few notable developments on the horizon:

Operator Training and Certification: With the increasing complexity and capacity of telehandlers, companies are placing emphasis on operator training and upskilling. Third-party certifications, like those from ANSI/ITSDF and OSHA, are becoming more standardized.

Electrification: While full electrification for high-capacity units remains in early stages due to weight and power demands, hybrid models and low-emission variants are being explored.

New Entrants and Competitive Pressure: Global OEMs are eyeing North America as a growth market for high-capacity telehandlers, which may increase competition and pressure legacy brands to continue innovating in load capacity, operator experience and machine adaptability.

Tim Palosaari, product manager, Pettibone:

Many new competitors are entering the high-capacity telehandler market every year. Competition is always a good thing for the consumer and requires OEMs to sharpen our pencils to deliver a compelling product. With the Pettibone brand nearing our 150th anniversary in 2031, we’re confident that the reliability of our products and our wealth of knowledge will keep us competitive for years to come.